Helium

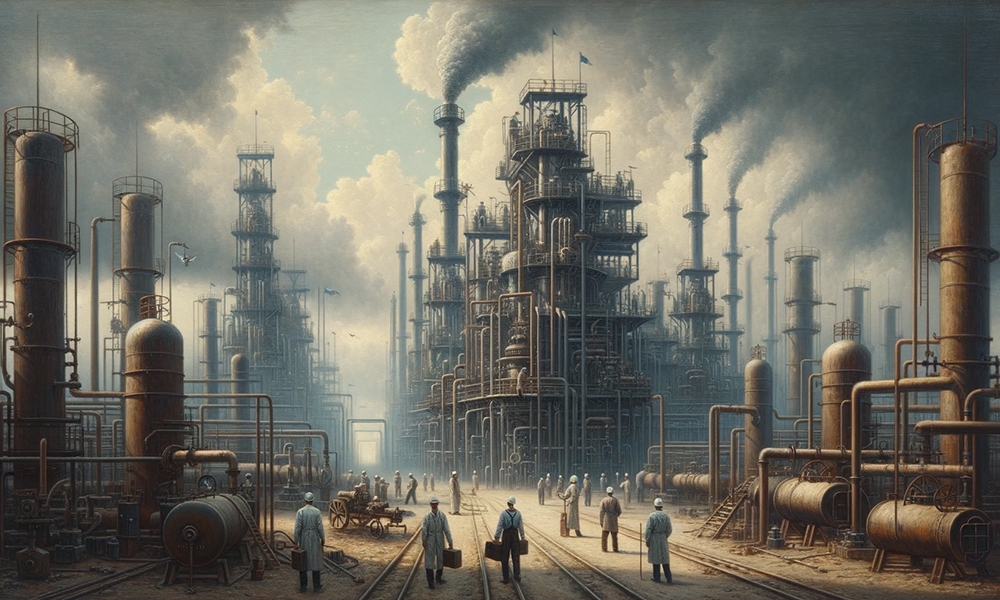

Helium inspections were developed for the Manhattan Project, dating back to World War II. With a 75+ year track record, it has been considered the “Gold Standard”.

Helium inspections were developed for the Manhattan Project, dating back to World War II. With a 75+ year track record, it has been considered the “Gold Standard”.

Lineriders provides world-class Helium inspections on any size project. We have our own process for ensuring that “slugging” of gases does not occur. Our Helium inspections are much more than “box checking”. This leak testing generates stakeholder value by ensuring the asset is leak free and completing repairs before the contractors have left site. Doing so achieves the highest level of quality assurance by protecting the workers on site, the public at large, the environment, and the asset.

Lineriders will guide you through the entire process. Including your leak detection contractor in your discussions early on will save time and money. Unfortunately, Helium has become expensive and difficult to source. Allow us to help you navigate the Helium market to source and acquire your tracer gas. Combining our expertise with yours, we will accomplish a leak free facility on any sized project. Contact us today to discuss your next endeavor.

Check Out Our Blog

Leak Detection Technologies: Evolution

The narrative of leak detection within the oil and gas [...]

Replacing Helium in Leak Detection

Lineriders' Advanced Proprietary Process For decades, helium has been the [...]

The Need for a Helium Replacement in Leak Detection

The Need for a Helium Replacement in Leak Detection In [...]